Our Specialization

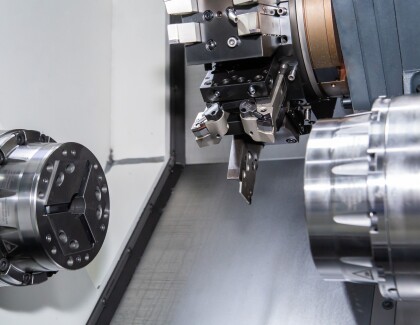

IMPA Precision produces parts with highly precise dimensions and parts with high visual requirements for its customers. The processes we use include 3- and 5-axis milling, turning (also with powered tools), wire EDM, and combinations of these methods. IMPA Precision can also fully support you in the field of surface treatments.

IMPA Precision specializes in machining various types of steel, aluminum, stainless steel, titanium, nickel alloys (such as Inconel), and other high-quality materials.

At IMPA Precision, you can turn to us with prototypes, initial series, single pieces, and large series. These are produced with a highly favorable price-to-quality ratio.

IMPA Precision is ISO 9001:2015 certified.

Whatever your needs may be, we stand for quality, both in complex and simple projects.